|

|

|

The Technology

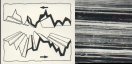

All machined metal surfaces have a surprising amount of surface roughness, even after the break in period has been completed. A magnified view shows these surfaces include microscopic peaks and valleys that present difficulties for lubrication. Complete separation of contact surfaces requires that an oil layer with a thickness of at least twice the height of the tallest peak be maintained in order to eliminate metal to metal contact. To assist in surface separation, additives are used in lubrication formulation to help smooth the peaks and valleys. All current oil formations include some method of accelerating surface improvement. Separating oils by their built-in surface improvement technology yields 3 lubrication classifications. |

|

Conventional

Lubrication

The first oils simply formed a liquid cushion between moving parts and allowed microscope surface roughness to slowly smooth through abrasion. Later, chemicals were added which formed metallic salt layers on the sliding surfaces to slowly wear away the surface irregularities. |

|

Solid Lubrication

The follow-up development was a lubricating medium containing graphite, molybdenum, Teflon or other solid additives that formed a protective layer under pressure and filled the microscopic pits and valleys to form a smooth sliding surface. Instead of wearing away metal, they built up on the metal surface. |

|

Performance

Activated Lubrication - Opti-2 / Opti-4

This process involves neither abrasion nor build-up. It produces and action that causes the metal surfaces to restructure. The metal deforms and rapidly produces super smooth, hardened, sliding surfaces. The harder the engine is run, the more effective the lubricant becomes. |